The Power of Real-Time Supply Chain Analytics

Teresa Wingfield

December 27, 2022

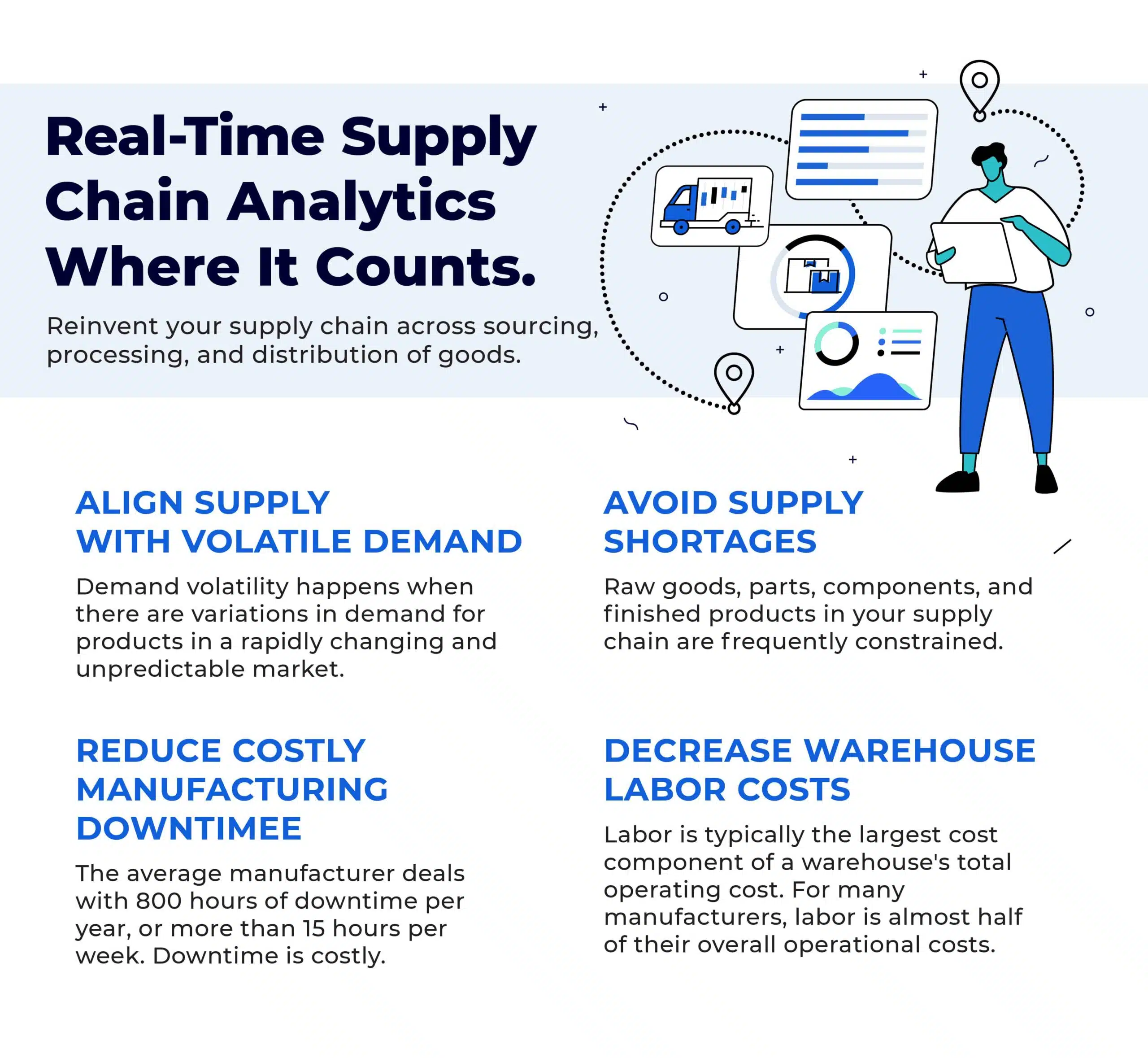

There are many areas where real-time data analytics helps businesses increase revenue and operate more efficiently. Manufacturers, for instance, can use real-time supply chain analytics to reinvent their supply chain across sourcing, processing, and distribution of goods, so they can adjust to changing conditions quickly and effectively. Manufacturers can get the visibility they need at any moment, in time to deal with some of their hardest supply chain challenges more effectively – including demand volatility, supply shortages, manufacturing downtime and high warehouse labor costs.

Demand Volatility

Demand volatility happens when there are variations in demand for products in a rapidly changing and unpredictable market. Many factors contribute to demand volatility. Examples include the changing customer preferences and behavior, competitive business maneuvers, upstream supply fluctuations, and your own product and price adjustments.

But how can you effectively align supply with demand when demand is volatile? Forecasts based on what happened in the past are inherently inaccurate in this type of environment. Accessing insights from real-time customer behavior and streamed point-of-sale data can help you understand demand as it’s happening more meaningfully. When used effectively, these insights can provide opportunities to:

- Source new or reallocate existing production components.

- Adjust production levels, shortening lead times and cycles.

- Ensure adequate inventory is available in the right quantity, at the right place, at the right time.

- Create or refine promotions to increase customer demand.

Supply Shortages

We have seen how the COVID-19 pandemic has posed significant challenges for supply chain dynamics and the kinds of business disruptions that it brought on across industries. Beyond the pandemic, the war between Russia and Ukraine and geopolitical concerns in East Asia have led to manufacturers reassessing where their suppliers and manufacturing facilities are located. To counter supply chain shocks, businesses rely on data analytics to help them determine what events are happening in their supply chain.

Can your data analytics help you determine which raw goods, parts, components, and finished products in your supply chain are constrained? Would you be able to determine the reasons why? If so, you may be able to leverage opportunities to buy missing production inputs from an alternative supplier or to resolve a transportation bottleneck by using another shipper. These are just two illustrations of how your business can use data analytics to resolve such challenges. Manufacturers should base decisions not only on whether sales margins will still be positive after adjusting sourcing and transportation, but also on the potential negative impact on the customer experience that supply chain constraints can cause.

Manufacturing Downtime

Downtime in manufacturing and labor costs in warehouses rank among one of the top reasons why there are operational inefficiencies. The average manufacturer deals with 800 hours of downtime per year – or more than 15 hours per week. Downtime is costly. For an automotive manufacturer, they can lose up to $22,000 per minute of downtime. As an increasing number of manufacturers incorporate more Internet of Things (IoT) devices on their plant floors, they also have many opportunities to analyze data from them in real time using advanced analytics and machine learning techniques. Manufacturers would be able to identify and resolve potential problems with production-line equipment before they happen and spot bottlenecks and quality assurance issues faster.

High Warehouse Labor Costs

Labor is typically the largest cost component of a warehouse’s total operating cost. For many manufacturers, labor is almost half of their overall operational costs.

Do you have the latest insights into changing demand so that you can dynamically scale your warehouse workforce based on business needs? Traditional demand forecasting helps manufacturers understand demand and product movement on a weekly, monthly, and yearly basis. However, manufacturers need to move faster if they want maximum efficiency. For example, real-time insights into demand can lead to faster production scheduling adjustments to either avoid or shorten the time of stockouts and to reduce unnecessary labor costs such as overtime.

Real-time supply chain analytics is a must-have for proactive, ambitious companies – not a nice-to-have. For manufacturers, whose success relies on the efficiency of their sourcing, processing, and distribution – real-time supply chain analytics should be a part of their business best practices. The bottom line is that real-time supply chain analytics will help manufacturers increase their revenue targets and metrics for business success.

Additional Resources:

- How to Maximize Business Value with Real-Time Analytics

- How the Right Data Platform Approach Unleashes Competitive Advantage

Subscribe to the Actian Blog

Subscribe to Actian’s blog to get data insights delivered right to you.

- Stay in the know – Get the latest in data analytics pushed directly to your inbox.

- Never miss a post – You’ll receive automatic email updates to let you know when new posts are live.

- It’s all up to you – Change your delivery preferences to suit your needs.